Bory

Maucotools LBM 250 Dual System

Maucotools LBM 250 Dual System

Couldn't load pickup availability

Please get in contact for an individual quote including shipping from our UK stock,

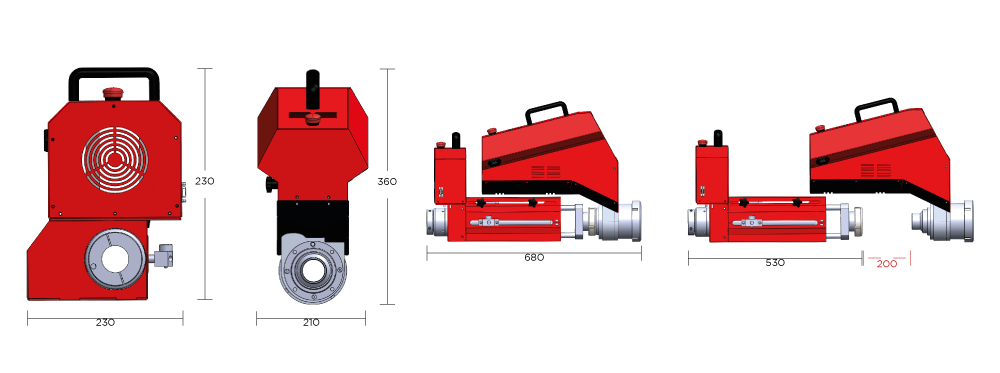

LBM-250DUAL SYSTEM is Maucotools smallest On-Site and Portable Line boring and Bore Welding machine. (the 250 indicates the size range and not the bar diameter)

This model has developed mainly for maintenance and repair heavy construction and agricultural equipment, buckets, loader arms, articulation units, dog bones etc

Internal Line Boring: 22mm - 250mm

Internal Automatic Bore Welding Ø : 22mm - 250mm

External Automatic Bore Welding Ø : 22mm - 250mm

The MAUCOTOOLS DUAL SYSTEM is a groundbreaking solution for on-site machining, designed with patented modularity. It features two lightweight modules, each weighing 17kg, allowing for easy transport and operation without heavy lifting equipment. Both the Rotation and Feed Modules have independent control panels, enabling simultaneous machining tasks like facing and welding. This system offers unparalleled efficiency, precision, and safety, with built-in protection systems for motor and error prevention, making it ideal for professionals handling complex projects in the field.

MAUCOTOOLS PATENTED DUAL SYSTEM KEY FEATURES & ADVANTAGES

Truly Portable Design: Unlike conventional “portable” machines that are merely transportable, the MAUCOTOOLS DUAL SYSTEM divides its weight between two modules, each weighing approximately 17kg. This makes the machine genuinely portable and manageable by a single operator without the need for lifting tools. Modular construction:

The DUAL SYSTEM is composed of two separate modules:

1- Rotation Module: Responsible for the rotational motion during operations likeline boring and facing. This has two gears gand electric spoeed control giving a range of 54-423rpm available in 110 or 240v, hydraulic power options are also available

2- Feed Module: gives axial feed for boring along with synchronous feed and rotation for overlay welding. Remote control operated. Unlimited axial feed range in 200mm increments, fast traverse button, and adjustable limit switch stops for coming up to a shoulder of the end of a bore

Simultaneous Dual Operation: Thanks to independent control panels, the Rotation and Feed Modules can be operated concurrently, enabling simultaneous machining tasks—such as performing a facing operation on one workpiece while executing overlay welding on another. This can also be supplemented by a mechanical feed gearbox (part number AV-S ) that allows you to be bore welding with the feed module on one setup whilst boring with the rotational module and the mechanical feed unit on another setup, giving twice the output with one machine and a feed unit.

Anti-Vibration Robustness: Both modules, whether used together or separately, ensure structural stability, minimizing vibrations and maintaining high precision during all machining tasks.

Boring Bars – the LBM 250 kit comes with two 40mmx1000mm modular bars and a 20mmx1000mm small bar, these bars use a 16mm diameter tool holder giving excellent rigidity. The modular bar system gives the possibility to use the 250 with the full range of reducing and increasing bar kits up to a 60mm bar

Please get in contact for a individual quote including shipping from our UK stock,

For sales outside of the UK and Ireland please get in touch and we can put you in contact with the dealer in your country

price shown is for a 110v machine, 240v and hydraulic machines are also available, please get in touch

price shown is plus VAT and plus shipping from our UK workshops

Share